COATING TYPE - Basic

|

ГОСТ 9466 — 75 |

Э – 09Х1М - ТМЛ-1У-d - ТД Е 15 — Б20 |

ISO: 3580-А-Е CrMo1 B 2 2

AWS: A5.5: E6015-B2

ТУ У 25.9-34142624-014:2017

COATING TYPE - Basic

|

ГОСТ 9466 — 75 |

Э – 09Х1М - ТМЛ-1У-d - ТД Е 15 — Б20 |

ISO: 3580-А-Е CrMo1 B 2 2

AWS: A5.5: E6015-B2

ТУ У 25.9-34142624-014:2017

PURPOSE AND FIELD OF APPLICATION

Electrodes HR-1U are designed for manual arc welding with direct current of reverse polarity in all spatial positions, except the vertical down, the equipment and pipelines from steel 12MH, 15ХМ, 20ХМЛ, 12Х2М1, 12Х1МФ, 12Х2МФБ, 12Х2МФСР, 20ХМФЛ, and 15Х1М1ФЛ grades, that operate at a temperature of up to 540 ° С, as well as heating surfaces elements of boilers made of steel 12Х2М1, 12Х1МФ, 12Х2МФБ, 12Х2МФСР grades, irrespective of operating temperature.

SPECIAL PROPERTIES

Welding electrodes HR-1U provide metal high resistant to porosity while welding with an elongated arc. Electrodes allow to do narrow cut welding with a common angle of bevel edge not less than 15º. Welding should be done with a short arc on the clean edges.

APPLICATION CONDITIONS

Deposition rate factor – 9,0 g/A.hr. Electrode consumption per 1 kg of deposited metal 1,5 kg. Electrodes are designed for welding in all the spatial positions except the vertical down one.

REDRYING BEFORE WELDING

At the normal storage conditions, the redrying is not required. In case of moisture redrying before welding: 400±20 ºС; 1-1,5 hours. Max. 3 times. Moisture content in the coating should not exceed 0,4%.

CHEMICAL CONTENT OF DEPOSITED METAL, %

| Mn | Si | C | P | S | Cr | Mo | V |

| 0.5-0.9 | 0.15-0.40 | ≤0.12 | ≤ 0.035 | ≤ 0.025 | 0.8-1.2 | 0.4-0.7 | - |

MECHANICAL PROPERTIES OF WELD METAL

| Tensile strength, MPa | Elongation, % | Impact strength, J/сm² |

| ≥470 | ≥18 | ≥88 |

Welding should be done with a short arc on the clean edges.

PACKAGING DATA

| Diameter, mm | Length, mm | Welding current, A | Units per package, pcs | Weight of packing, kg |

| 3 | 350 | 80-110 | 92 | 2.5 |

| 4 | 450 | 110-150 | 82 | 5 |

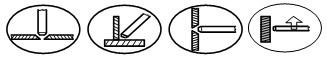

WELDING POSITIONS

PA PB PC PF

PE PD

ДСТУ EN ISO 6947